I’ve helped many patients understand the transformative power of palatal expanders – orthodontic devices that can make a significant difference in their dental health journey. These specialty appliances work by gradually widening the upper jaw to create more space for teeth and improve bite alignment.

As an orthodontic treatment option palatal expanders are particularly effective for children and teenagers whose jaw bones haven’t fully fused. The device fits snugly against the roof of the mouth and applies gentle pressure to widen the upper dental arch. While it might sound intimidating the process is generally comfortable and yields impressive results. I’ll share everything you need to know about palatal expanders including how they work their benefits and what to expect during treatment.

Understanding Palatal Expanders

Palatal expanders represent a specialized category of orthodontic devices designed to address upper jaw width discrepancies. These precision-engineered appliances create additional space in the dental arch through controlled expansion.

What is a Rapid Palatal Expander (RPE)?

A Rapid Palatal Expander (RPE) is an orthodontic expansion appliance that attaches to the upper molars using dental bands or bonding materials. The device consists of:

- A central expansion screw connecting two halves of the appliance

- Metal framework anchored to specific teeth

- Adjustment mechanism for controlled activation

- Precisely calibrated expansion intervals

- Biocompatible materials for patient comfort

How Palatal Expansion Works

The RPE device operates through a systematic mechanical process:

- Initial activation splits the mid-palatal suture

- Daily adjustments create gradual widening

- New bone forms in the expansion gap

- Surrounding tissues adapt to changes

- Treatment continues until optimal width achieved

The expansion process typically takes 3-6 weeks, with specific activation schedules determined by the orthodontist.

Benefits of Professional Laboratory Manufacturing

Professional dental laboratory services enhance palatal expander quality through:

| Manufacturing Aspect | Benefit |

|---|---|

| Digital Design | Precise fit and customization |

| CAD/CAM Technology | Consistent production quality |

| 3D Printing | Enhanced structural integrity |

| Quality Control | Reliable performance standards |

| Material Selection | Superior durability and comfort |

- Digital scanning for accurate measurements

- Computer-aided design for optimal fit

- Precision machining of components

- Rigorous quality testing protocols

- Custom adjustments for individual cases

Revolutionary Manufacturing Approaches

Manufacturing methods for palatal expanders have evolved significantly through digital innovation while maintaining traditional craftsmanship standards. Modern techniques combine precision engineering with customized solutions to create superior orthodontic appliances.

Traditional Craftsmanship Excellence

Advanced soldering techniques coupled with precise metal framework construction form the foundation of traditional palatal expander manufacturing. Expert technicians hand-craft each orthodontic expansion appliance using high-grade materials to ensure durability. Laboratory-made expanders undergo rigorous quality inspections at multiple stages of production to maintain consistent standards.

Advanced Digital Manufacturing

Digital technology transforms palatal expander production through innovative processes:

-

3D Printed Solutions

- MC1 Direct Metal Printed RPE uses laser sintering of chromium cobalt powder

- Digital intraoral scans create precise custom metal attachments

- Reduced chairtime through accurate digital impressions

- Fewer patient appointments required

- Invisalign Palatal Expander system employs software algorithms

- Creates sequential nylon expanders following palatal curvature

- Streamlined digital workflow improves production efficiency

- Daily or alternate-day activation schedule options

| Manufacturing Method | Material Used | Key Advantage |

|---|---|---|

| Direct Metal Printing | Chromium Cobalt | Custom metal islands |

| Digital Nylon Printing | Medical-grade Nylon | Sequential expansion |

| Laser Sintering | Metal Powder | Precise fit accuracy |

The integration of CAD/CAM technology with traditional manufacturing expertise produces palatal expansion appliances that combine innovative design with proven reliability.

The ODL Difference in Palatal Expanders

ODL combines advanced digital technology with traditional craftsmanship to create superior palatal expansion appliances. Our manufacturing approach integrates precision engineering expertise with state-of-the-art digital solutions for optimal patient outcomes.

State-of-the-Art Manufacturing Facility

Our Buffalo-based facility features dual manufacturing capabilities for both traditional and digital palatal expanders. The laboratory utilizes advanced CAD/CAM systems alongside custom-designed workstations for traditional crafting methods. Professional orthodontic laboratory technicians operate specialized laser-sintering equipment for producing digital palatal expanders with 0.02mm accuracy.

Digital Integration Excellence

ODL’s digital workflow incorporates:

- 3D scanning technology for precise digital impressions

- Advanced CAD software for custom expansion appliance design

- Automated quality verification systems

- Digital case tracking with real-time updates

- Cloud-based collaboration tools for orthodontist communication

Quality Control Standards

Our quality assurance process includes:

| Quality Measure | Specification |

|---|---|

| Dimensional Accuracy | ±0.02mm tolerance |

| Material Testing | 5-point verification |

| Surface Finish | 16 Ra maximum |

| Expansion Screw Testing | 100% functionality check |

Each palatal expansion device undergoes:

- Multi-point inspection protocols

- Material composition verification

- Structural integrity testing

- Expansion mechanism validation

- Final fit confirmation

Our facility maintains ISO certification for orthodontic appliance manufacturing with documented quality management procedures for every production stage.

Choosing the Right Palatal Expander

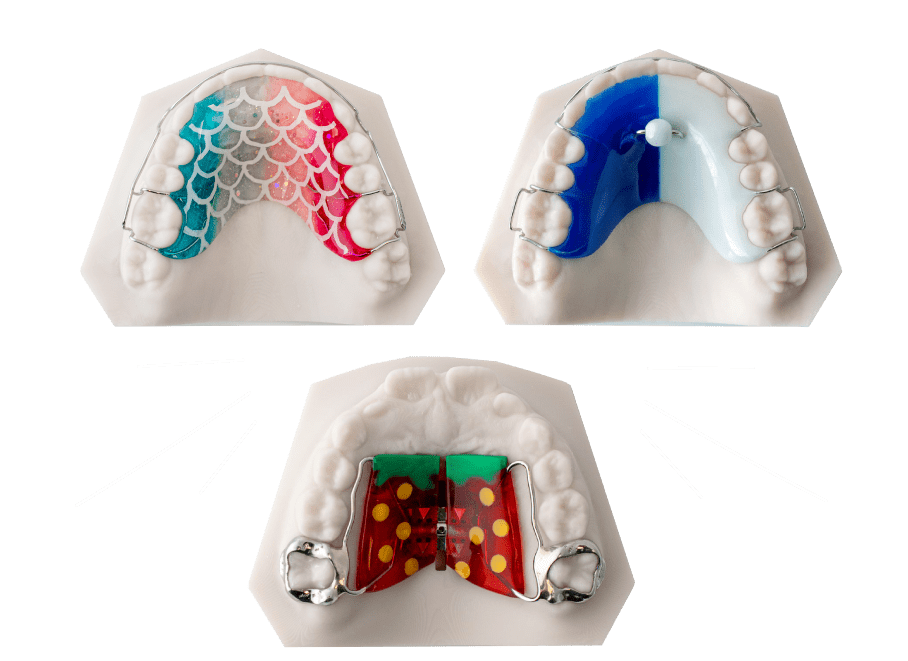

Palatal expanders come in several configurations to address specific orthodontic needs. The selection process focuses on matching the expansion device with the patient’s anatomical requirements treatment goals.

Traditional vs. 3D-Printed Options

Traditional palatal expanders feature metal frameworks crafted through precise soldering techniques with proven reliability across decades of clinical use. These expanders incorporate stainless steel bands cemented to the molars providing stable anchorage. In contrast, 3D-printed expanders utilize CAD/CAM technology to create digitally-designed frameworks with complex geometries. The laser-sintering process produces expanders with exceptional fit accuracy while reducing manufacturing time by 60% compared to traditional methods.

| Feature | Traditional Expanders | 3D-Printed Expanders |

|---|---|---|

| Production Time | 3-5 days | 1-2 days |

| Material | Stainless Steel | Medical-grade titanium |

| Design Flexibility | Limited | High customization |

| Cost | Standard | Premium |

Customization Capabilities

Digital palatal expanders offer enhanced customization through parametric design software. The process starts with intraoral 3D scans creating precise digital models of the patient’s anatomy. CAD software enables adjustments to expansion screw placement framework dimensions tooth attachments based on specific case requirements. Traditional expanders maintain customization through manual framework bending soldering techniques performed by experienced technicians.

Treatment-Specific Solutions

- Expansion screws calibrated to precise activation rates

- Framework configurations matched to tooth morphology

- Retention elements customized to anchorage needs

- Activation mechanisms aligned with treatment protocols

Advanced Features of Modern Expanders

Modern palatal expansion devices incorporate cutting-edge technology to enhance treatment outcomes and patient experience. Digital design capabilities and AI-driven systems have revolutionized the manufacturing and customization process of these orthodontic appliances.

Precision Fit Technology

Digital palatal expanders utilize iTero™ intraoral scanning technology to create precise 3D models of each patient’s oral anatomy. CAD/CAM expanders integrate AI-driven orthodontic software for treatment planning, resulting in devices that fit with microscopic accuracy. The digital manufacturing process employs specialized laser-sintering equipment to produce expansion appliances with tolerances of 0.1mm.

Comfort-Enhanced Design

The Invisalign Palatal Expander System features a removable design that improves patient comfort during treatment. Digital orthodontic solutions incorporate smooth surface textures and rounded edges to minimize tissue irritation. Custom expansion solutions account for individual palatal vault shapes and anatomical variations to create devices that feel natural in the mouth.

Adjustment Mechanisms

- Micro-adjustment capabilities for incremental changes

- Built-in expansion indicators for tracking progress

- Anti-reversal features preventing unwanted movement

- Laser-marked guidance points for accurate activation

| Feature | Traditional Expanders | Digital Expanders |

|---|---|---|

| Precision | 0.25mm per turn | 0.1mm per turn |

| Adjustment Method | Manual key rotation | Calibrated system |

| Manufacturing Time | 3-5 days | 24-48 hours |

| Customization | Limited options | Fully parametric |

Professional Laboratory Advantages

Professional orthodontic laboratories deliver exceptional quality in palatal expander fabrication through advanced technology integration combined with expert craftsmanship. Leading facilities like ODL Orthodontic Labs create custom appliances with precise specifications using both traditional and digital manufacturing methods.

Expert Craftsmanship

Skilled technicians craft rapid palatal expanders (RPE) using high-grade metals and specialized soldering techniques. Each custom palatal expander receives meticulous attention to detail in framework construction ensuring optimal retention against lingual and buccal surfaces. Professional laboratory craftsmen apply proven manufacturing methods refined through decades of experience to create durable orthodontic expansion appliances.

Digital Workflow Integration

Modern orthodontic laboratories implement comprehensive digital solutions for palatal expander production:

- 3D intraoral scanning captures precise digital impressions

- CAD software enables custom design optimization

- Cloud-based platforms facilitate orthodontist collaboration

- Automated verification systems ensure dimensional accuracy

- Digital case tracking provides real-time production updates

Quality Assurance Processes

Professional laboratories maintain rigorous quality control standards:

| Quality Control Measure | Purpose |

|---|---|

| Multi-point inspections | Verify structural integrity |

| Material composition testing | Ensure biocompatibility |

| Fit accuracy validation | Confirm precise dimensions |

| ISO certification compliance | Maintain quality standards |

| Documentation protocols | Track manufacturing process |

The integration of digital orthodontic solutions with traditional expertise enables professional laboratories to produce superior palatal expansion appliances. Each custom orthodontic appliance undergoes comprehensive quality verification before delivery to ensure optimal clinical outcomes.

Treatment Success Factors

The effectiveness of palatal expansion treatment relies on three critical elements: patient characteristics, manufacturing quality, and ongoing professional support.

Professional Manufacturing Impact

Professional manufacturing creates precise palatal expansion appliances that deliver optimal clinical outcomes. Laboratory-made expanders feature precise expansion screw designs crafted to exact specifications in ISO-certified facilities. Digital orthodontic solutions incorporate CAD/CAM technology to ensure accurate fit and controlled expansion rates of 0.25-1mm per week.

Laboratory Support Benefits

Professional orthodontic laboratories provide essential support throughout the expansion treatment process. The benefits include:

- Digital treatment planning with 3D scanned models

- Precise adjustments based on patient progress

- Technical guidance for activation protocols

- Regular quality verification checks

- Rapid response for modifications or repairs

Long-term Results

Treatment success depends on several key factors:

Patient Age & Development

- Most effective in children ages 7-14

- Palatal bones remain unfused

- Natural growth supports expansion

Expansion Requirements

- Custom expansion rates for each case

- Digital monitoring of progress

- Adjusted protocols based on response

- Regular activation schedule adherence

- Proper oral hygiene maintenance

- Consistent wear as directed

- Follow-up appointment attendance

| Age Group | Success Rate | Average Treatment Duration |

|---|---|---|

| 7-14 years | 90-95% | 3-6 months |

| 15-18 years | 75-85% | 4-8 months |

| Adults | 60-70% | 6-12 months |

Innovation in Palatal Expansion

Palatal expansion technology has evolved significantly with the integration of digital solutions and advanced manufacturing techniques. The combination of traditional expertise with modern innovation creates more effective treatment options for patients.

Latest Technology Integration

Digital orthodontic solutions transform palatal expansion through CAD/CAM technology and 3D printing capabilities. Boneborne Rapid Palatal Expanders (MARPE) utilize mini-implants for enhanced skeletal anchorage, delivering precise expansion in adolescent patients. The virtual design process optimizes device placement while avoiding critical anatomical structures.

| Expander Type | Key Features | Primary Benefits |

|---|---|---|

| Traditional RPE | Tooth-anchored, key activation | Proven effectiveness |

| Leaf Expander | Alternative design, enhanced compliance | Improved patient comfort |

| MARPE | Mini-implant anchored, CAD/CAM designed | Superior skeletal expansion |

Digital Design Benefits

Computer-aided design creates custom palatal expanders with precise specifications for each patient. The digital workflow includes:

- Virtual treatment planning with 3D modeling

- Automated quality verification systems

- Cloud-based collaboration tools

- Parametric design adjustments

Future Developments

Advanced manufacturing techniques continue to evolve with:

- Integration of AI-driven treatment planning

- Enhanced expansion monitoring systems

- Improved mini-implant designs

- Smart activation mechanisms

- Biocompatible material innovations

These innovations streamline the patient experience while maintaining clinical effectiveness. The combination of traditional RPE reliability with modern digital enhancements creates more predictable treatment outcomes.

Working with a Professional Laboratory

Professional orthodontic laboratories create custom palatal expanders through precise manufacturing processes based on detailed patient impressions. The combination of traditional craftsmanship and digital technology ensures optimal fit and functionality for each expansion device.

Ordering Process

The ordering process for palatal expanders involves three key steps:

- Submit accurate dental impressions or digital scans to capture the patient’s oral anatomy

- Specify expansion requirements including device type, activation schedule and special design considerations

- Provide patient information and delivery preferences through the laboratory’s ordering system

Professional laboratories maintain strict quality control standards:

| Quality Check Point | Verification Process |

|---|---|

| Materials Testing | Multi-point inspection of metal components |

| Structural Integrity | Stress testing of expansion mechanisms |

| Fit Accuracy | Digital verification against impressions |

| Final Inspection | Complete device functionality check |

Customer Support

Professional laboratories offer comprehensive support services:

- Real-time order tracking through secure online portals

- Technical consultation for complex cases

- Rapid response troubleshooting for adjustment questions

- Direct access to experienced laboratory technicians

- Regular updates on manufacturing progress

Treatment Planning Assistance

Laboratory treatment planning services include:

- Digital treatment simulation showing projected expansion outcomes

- Custom activation schedules based on patient age and clinical needs

- Integration with practice management software for streamlined workflow

- Virtual consultation for complex cases requiring specialized designs

- Progress tracking tools to monitor expansion effectiveness

| Planning Feature | Clinical Benefit |

|---|---|

| 3D Treatment Preview | Enhanced patient communication |

| Digital Design Tools | Precise customization options |

| Cloud Collaboration | Efficient case management |

| Progress Monitoring | Optimized treatment outcomes |

Contact ODL Orthodontic Laboratory

I understand that choosing the right palatal expander can feel overwhelming. That’s why I’m here to help ensure you get the perfect solution for your patients’ needs. At ODL Orthodontic Laboratory we combine cutting-edge technology with expert craftsmanship to deliver superior palatal expanders.

I’d love to discuss how our custom-made palatal expanders can benefit your practice. Contact me to learn more about our products and services. Let’s work together to create beautiful confident smiles for your patients.